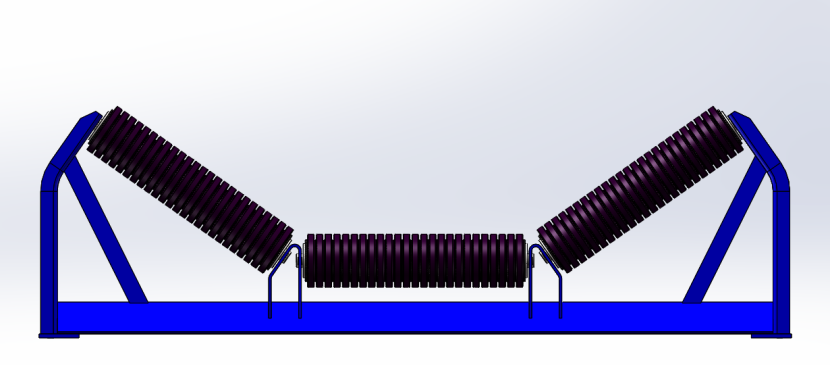

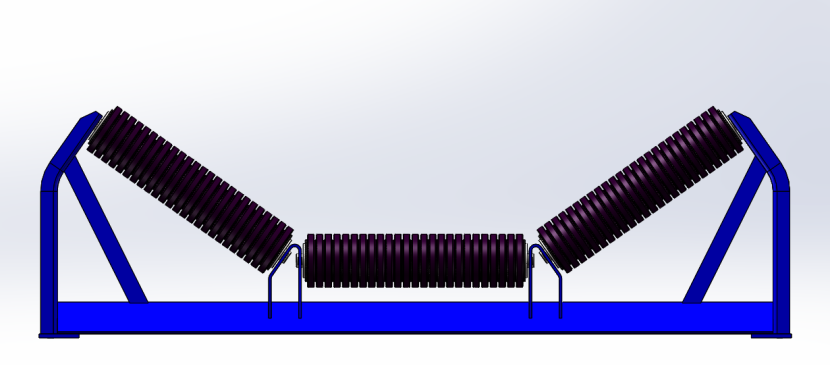

Buffer idler group

The buffer idler is installed below the material receiving section of the conveyor to reduce the impact of materials on the conveyor belt during blanking, so as to prolong the service life of the conveyor belt. The spacing of buffer idlers is generally 100-600mm. Buffer idler is a kind of idler mainly developed for corrosive environments such as coal washing plant, coking plant and chemical plant. It has more than 10 times the toughness of ordinary metal, five times the service life of traditional column shoes, corrosion resistance, flame retardant, antistatic, light weight and other characteristics. It is widely used in mining. The special polymer material for idler body has mechanical properties similar to bronze, good wear resistance, good self-lubricating performance and no damage to the belt. The buffer idler has excellent anti-corrosion performance. The roll body and seals are made of polymer materials, which are corrosion-resistant. When used in corrosive occasions, the service

产品详情

中文

中文

English

English

创为先·质为本·精为魂

创为先·质为本·精为魂